⭐ FEATURED

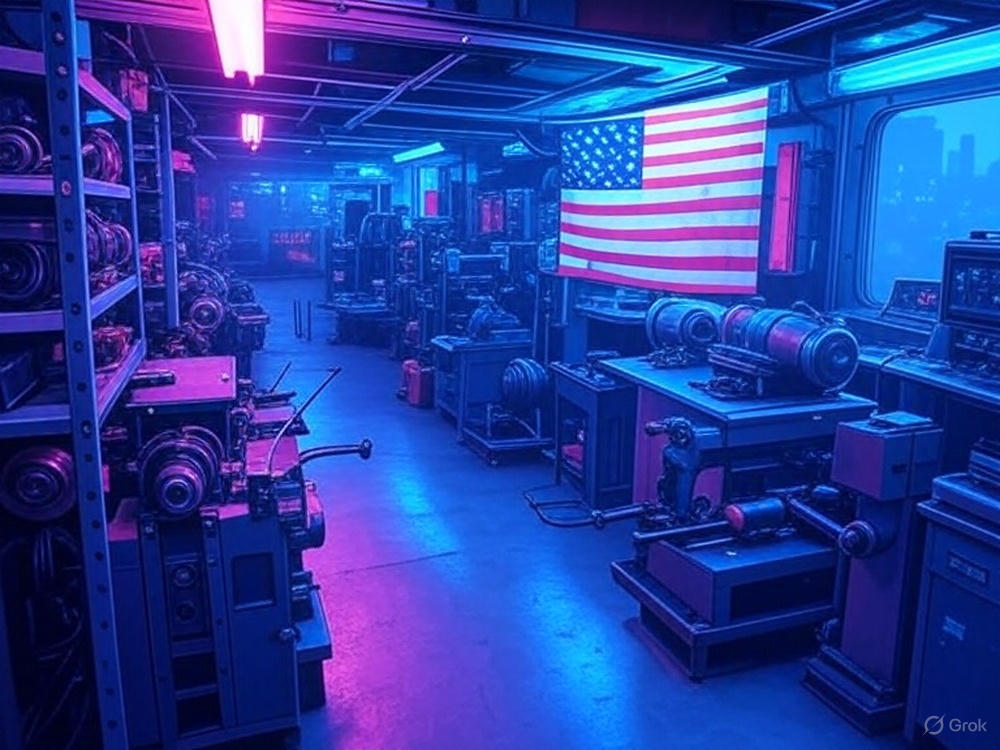

Machine Shop Technician

Atomic Industries • Detroit, MI | $80000

Atomic Industries is pioneering the automation of the tool and die industry using advanced AI and robotics to enable rapid, high-precision manufacturing of complex parts. Our mission is to reindustrialize America by revitalizing domestic manufacturing capabilities, reducing dependency on foreign supply chains, and accelerating innovation in hard tech sectors like defense, aerospace, and automotive. As a Machine Shop Technician, you will operate and maintain a variety of machine tools, including CNC mills, lathes, and grinders, to produce precision components. Responsibilities include setting up machines according to blueprints and specifications, monitoring production runs, performing quality inspections using micrometers and calipers, troubleshooting equipment issues, and collaborating with engineers to optimize processes. This role requires hands-on experience with machining operations, knowledge of G-code programming, and a commitment to safety protocols in a fast-paced startup environment. Ideal candidates have 3+ years of experience in a machine shop, familiarity with CAD/CAM software, and a passion for building the future of American manufacturing. Join us in transforming how the world makes things, from prototypes to production-scale runs, while contributing to national security and economic resurgence.

View Details →⭐ FEATURED

Manufacturing Engineer

NOX Metals • Detroit, MI | $70176

NOX Metals is a Y Combinator S25 startup revolutionizing the metals manufacturing industry by creating a modern factory that delivers fast, low-cost metals to bolster America's industrial base. We are vertically integrating our operations, beginning with CNC aluminum blocks, to address critical supply chain challenges and promote the reindustrialization of America. As a Manufacturing Engineer, you will play a pivotal role in designing, optimizing, and overseeing manufacturing processes in our new Detroit factory. Responsibilities include setting up and programming CNC machines, troubleshooting production issues, ensuring quality standards, and innovating to enhance efficiency and reduce costs. This position requires expertise in mechanical engineering principles, CNC operations, and manufacturing systems. Join our small, ambitious team to make a real impact by building industrial infrastructure and moving physical products in a hard tech environment dedicated to domestic manufacturing revival.

View Details →Chief Roboticist

Mundane • Palo Alto, CA | $350000

Mundane is a seed-stage robotics startup founded by Stanford robotics researchers, specializing in developing practical, deployable robot software for commercial cleaning and other mundane tasks, emphasizing real-world applications over lab demonstrations. We are seeking a Chief Roboticist to architect our humanoid robot fleet, leveraging expertise in ROS2, state machines, behavior trees, middleware, and more. The ideal candidate has 5+ years of experience deploying robots in real-world environments and is eager to escape bureaucratic constraints to focus on shipping innovative products. Our mission is to automate labor-intensive tasks, reshaping the economy through advanced robotics and contributing to the hard tech and reindustrialization movement in America. This role offers the chance to lead groundbreaking work in a fast-paced, venture-backed environment, driving the future of autonomous systems that enhance productivity and efficiency across industries.

View Details →Manufacturing Engineer

Nia Therapeutics • Allston, MA | $110000

Job Description

Nia Therapeutics develops brain computer interfaces that restore memory function after brain injury and degenerative disease. Our team includes leaders in the fields of engineering, cybersecurity, neuroscience, and neurosurgery, and our technology has the potential to revolutionize the treatment of patients with memory loss. This position is responsible for leading the process engineering and production support for the company’s core product line. You will transition advanced prototypes from R&D to scalable, high-quality production; provide technical leadership and support for continuous improvement team efforts focused on process improvement and optimization; and provide engineering leadership for design for manufacturing, manufacturing bring-up, test development, equipment selection, operation and optimization.

Responsibilities

- Leads process engineering and production support activities at contract manufacturing partners.

- Leads the introduction of new products into manufacturing.

- Collaborates with R&D and suppliers to improve product robustness and manufacturability both pre- and post-release.

- Resolves complex production issues at scale, from root cause identification to validated solution deployment.

- Writes process procedures, change orders, equipment specifications, validation plans, and reports.

- Performs research on technology, equipment and tooling to improve process quality, yield or cost.

- Generates proposals for equipment purchase and implementation, including cost of ownership, ROI and benefit analysis.

- Provides technical guidance and leadership for continuous improvement including process improvements and product manufacturability improvements.

- Performs engineering design of test equipment, assembly equipment, fixtures and tools; performs IQ/OQ/PQ validation activities

- Responsible for establishing the Manufacturing Quality Plan (MQP) for a product.

- Role has no management responsibility, but is expected to provide technical guidance and engineering mentorship to more junior members of the technical team.

Qualifications

- B.S. in Engineering and 8+ / 11+ years of experience or an advanced degree and 6+ / 9+ years of experience.

- Experience taking multiple products from concept to manufacturing.

- Proficiency with CAD modeling tools (e.g. SolidWorks).

- Experience integrating PCBs and electronic subassemblies into mechanical designs.

- Experience with manufacturing methods such as injection molding, mold design, fixturing, machining, and laser welding.

- Experience developing Class III active implantable devices.

- Experience with neural leads and IPG production preferred.

- Experience implementing robust manufacturing processes at the micron-millimeter scale.

- Experience selecting materials for implantable devices (ISO-10993) preferred.

- Experience working with and managing contract manufacturing partners.

- Excellent organizational, communication and teamwork abilities.

- Strong analytical and problem-solving skills and expertise using structured analytical techniques.

View Details →Mechanical Design Engineer

Catalyx Space • San Francisco, CA | $130000

Catalyx Space is at the forefront of space reentry technology, fostering a racing team culture that emphasizes speed, precision, and collaboration. As a Mechanical Design Engineer, you will play a pivotal role in designing mechanical systems for space vehicles, including deployable structures and separation systems. Responsibilities include using CAD tools to create detailed designs, performing structural analyses, and collaborating with cross-functional teams to ensure designs meet rigorous space environment requirements. This position requires strong problem-solving skills, knowledge of materials science, and experience with prototyping and testing. Join a dynamic startup contributing to America's reindustrialization by advancing domestic space manufacturing capabilities, working alongside passionate founders committed to innovation in hard tech.

View Details →Propulsion Engineer II

Catalyx Space • San Francisco, CA | $120000

As a seed-stage company, Catalyx Space is building AWS-like infrastructure for space, providing turnkey reentry capsules and orbital platforms to democratize access to space for experiments and demos, fostering innovation in hard tech and reindustrializing American aerospace manufacturing. In the role of Propulsion Engineer II, you will design and optimize propulsion systems for spacecraft, including thrusters for attitude control and de-orbit maneuvers. Key duties involve modeling fluid dynamics in propulsion components using tools like MATLAB or ANSYS, specifying propellants and feed systems, integrating engines with structural elements, and overseeing testing in simulated space conditions. You'll work on hybrid or electric propulsion technologies, ensuring reliability for reentry missions, and collaborate with mechanical engineers on heat shield interfaces and assemblers for hardware integration. This position requires expertise in aerospace propulsion principles, experience with CAD for component design, and hands-on involvement in fabrication processes like welding and machining. Requirements: Bachelor's or Master's in Aerospace Engineering, 3-5 years in propulsion development, knowledge of orbital mechanics, and passion for building next-gen space hardware. Be part of a dedicated team of cracked founders accelerating America's space industry through domestic engineering excellence.

View Details →Mechanical Design Engineer II

Catalyx Space • San Francisco, CA | $130000

Catalyx Space, a seed-stage aerospace startup backed by Y Combinator's Hf0 and Founders Inc, is pioneering end-to-end responsive space transportation solutions, including reentry capsules and orbital labs, to enable rapid space experiments and technology demonstrations. As a Mechanical Design Engineer II, you will lead the design and development of structural components for spacecraft, focusing on deployable mechanisms, thermal protection systems, and assembly integration. Responsibilities include generating 3D models in CAD software such as NX or SolidWorks, performing stress and vibration analysis using FEA tools, selecting materials suitable for space environments (e.g., composites, alloys), and coordinating with manufacturing partners for prototyping via CNC machining and additive manufacturing. You'll collaborate with propulsion and avionics teams to ensure designs meet mission requirements for reentry survivability and orbital operations, while iterating based on test data from vacuum chambers and thermal cycling. This role emphasizes hands-on building in a fast-paced environment, where you'll contribute to America's reindustrialization by advancing domestic hard tech capabilities. Requirements: Bachelor's in Mechanical Engineering, 3-5 years experience in aerospace design, proficiency in GD&T, and familiarity with space qualification standards. Join our racing team culture to push the frontiers of space tech.

View Details →Aerospace Engineer

Allen Control Systems • Austin, TX | $110000

At Allen Control Systems, a Series A-funded defense tech company, our mission is to revolutionize counter-drone warfare by creating robotic systems that autonomously detect, track, and neutralize aerial threats, thereby safeguarding military and civilian assets. As an Aerospace Engineer, you will contribute to the aerodynamic design and propulsion integration of our advanced platforms, ensuring optimal flight dynamics and stability. Key responsibilities encompass simulating airflow using CFD tools like ANSYS, designing airframes and control surfaces for high-speed maneuvers, integrating sensors and actuators for precise targeting, and conducting wind tunnel tests to refine prototypes. You'll work closely with the robotics team to embed machine learning algorithms for real-time decision-making, while adhering to ITAR regulations and defense industry standards. This position requires expertise in aerospace principles, including fluid mechanics and structural analysis, and involves hands-on fabrication using techniques like composite layup and CNC machining. Ideal candidates hold a Bachelor's in Aerospace Engineering with 2-5 years of experience in drone or missile systems, strong analytical skills, and a drive to innovate in hard tech. Be part of a locked-in founding team reindustrializing America's defense capabilities through domestic manufacturing and cutting-edge engineering.

View Details →